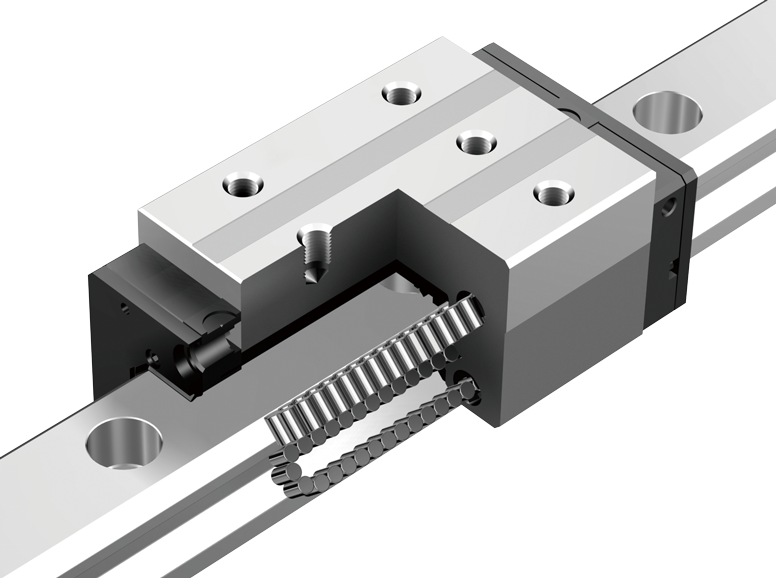

Rolling elements and fluid films, commonly known as linear bearings, reduce friction in motion systems where motion follows a straight or occasionally curved route.

They should not be confused with a spinning bearing cage. The phrase Linear Bushing SRS (รังลูกปืน LM Guide SRS, which is the term in Thai) indicates this. Roughly speaking, there are two types of sliding surfaces: those that depend on lubrication and low friction surfaces, and ball and roller types that take use of the rolling motion of rolling parts.

Bearings of the Rolling Type

When it comes to, Open ball cages, also called guideposts or leader pins, work in tandem with die posts to provide precise direction for the upper and lower dies to close.

Both of them offer reduced beginning friction when compared to bushings of the slide type.

- Ball bushing rails are successfully end-mounted and can span a specific distance between supports. Profile rail mounting usually requires support all the way along the rail, therefore careful surface preparation is required. The length of the stroke is determined by the quantity of elements, though. Long strokes might therefore be more useful.

- Most suppliers of linear bearings include a selection guide that leads the customer through the design challenge. Applications are considered ranging from semi-precision ones such as saw guides, to precise ones like machine tools, and from low-precision ones like drawer slides. Systems with different actuation options can be supplied by a multitude of providers

Sintered metal bushings have lost some of their market share to self-lubricating polymer linear bushings. The polymer itself—typically PTFE—is what gives the running shaft its slickness. They are appealing to the food packaging sector because of their ability to work without lubricants and resistance to washdown chemicals. They can work on unshardened shafts that are incredibly resistant to corrosion.

Conclusion

The maximum projected speed and acceleration, the length of stroke, and the maximum force the system would endure are some of the details engineers must know before sizing a system. It is not reproducible. The system’s moment loads acting along the x, y, and z axes must also be considered. Selecting a system is influenced by various factors, including noise and vibration levels and maintenance.

Hence, when it comes to making a decision about Bearing cage LM Guide SRS, it is always necessary to make the right choice at the right time.

Comments